Biosio Oil Mill

Where we produce our D.O.P. Oil Laghi Lombardi – Lario

Frantoio Oleario di Biosio – Biosio Oil Mill – Bellano, a highly technological plant built in collaboration with the Comunità Montana Valsassina, Valvarrone, Val d’Esino and Riviera.

Poppo Azienda Agricola - Farm by Enicanti Leonardo

The facility has been developed and refined over the years to provide a service for local olive growers, allowing them to transform their precious olives into high-quality extra virgin olive oil.

The Mountain Community, driven by the desire to revitalize struggling mountain agriculture, helped establish and modernize the facilities to enable the efficient processing of small batches of olives with the right equipment.

The resulting oil, a true functional food, delights the tables of producers and discerning consumers always in search of high-quality niche products.

Olio D.O.P.

The origins of the oil mill

The Poppo farm of Leonardo Enicanti was founded in 2004, building on the olive-growing activities started by Mauro Denti.

Mauro had started growing olive trees in 1992 with an initial planting of 120 plants on land previously used for viticulture, an activity that required a lot of work that was not repaid by qualitative results, resulting in poor appreciation of the product.

Already in 2004 the company obtained the D.O.P. Laghi Lombardi Lario certification, in parallel with the first positive feedback from attentive customers who were looking for a high-quality local product. The growing demand, not compensated by the small quantities produced at the time, stimulated the growth of the company’s surfaces invested in olive trees. Thanks to arduous planting work, given the considerable difficulties due to the impervious orography of the land, in just a few years we were able to cultivate around 400 olive trees.

In 2006 the company took a big step, which would later prove to be strategic and rewarding. Thanks to the contribution and great interest of the Comunità Montana Valsassina, Valvarrone, Valdesino and Riviera, a new small-scale oil plant of the Pieralisi company was inaugurated, with an hourly capacity of about 3.5 q but with cutting-edge technical solutions for the Larian olive sector, a processing line with a continuous two-phase system managed with cold processing, which led to a qualitative improvement of the oil produced on the Lario, promptly appreciated by consumers.

The Poppo farm is therefore constantly attentive to new developments in oil technology and ready to implement innovative solutions. At the same time, high vigilance is constantly maintained on the freshness and health of the olives to be pressed, in order to return to the producer and consequently guarantee the consumer a high quality extra virgin olive oil.

The production cycle

Delivery of olives

Milling

BIOSIO OIL MILL

All our awards and recognitions

Master of Olive Oil Internation Contest

Montecarlo 2023

GAMBERO ROSSO: Tre Foglie 2015

Recognition to the Mauro Olive Groves

CITTA’ DI SORRENTO: Menzione di Merito 2015

13° Sirena d’Oro Sorrento

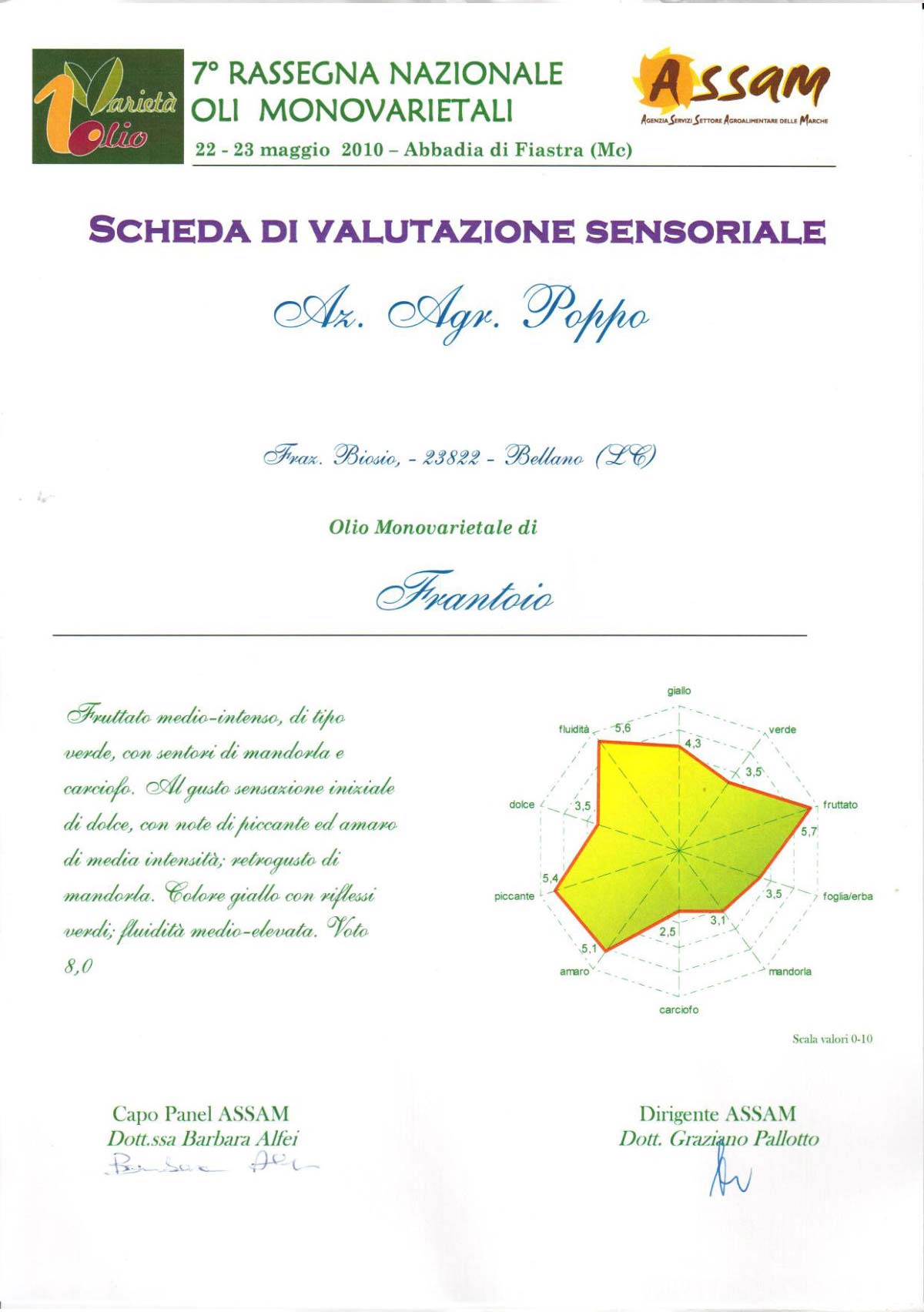

7° RASSEGNA NAZIONALE OLI MONOVARIETALI

Sensory Evaluation Sheet 2010: RATING 8.0

SLOW FOOD: Olio Slow 2018

Company Award

Sirena d'Oro di Sorrento 2023

LIGHT FRUITY Second place